by Holger Höltke on 09/27/2020

MM-Fiber Coupling Principles – Part 2

To couple laser light into or out of a multi-mode fiber, several optical coupling principles are commonly used in our industry. Over the next two articles, we compare the two most common one: the widely spread lens-prism-coupling and the direct or butt coupling.

Lens-prism-coupling

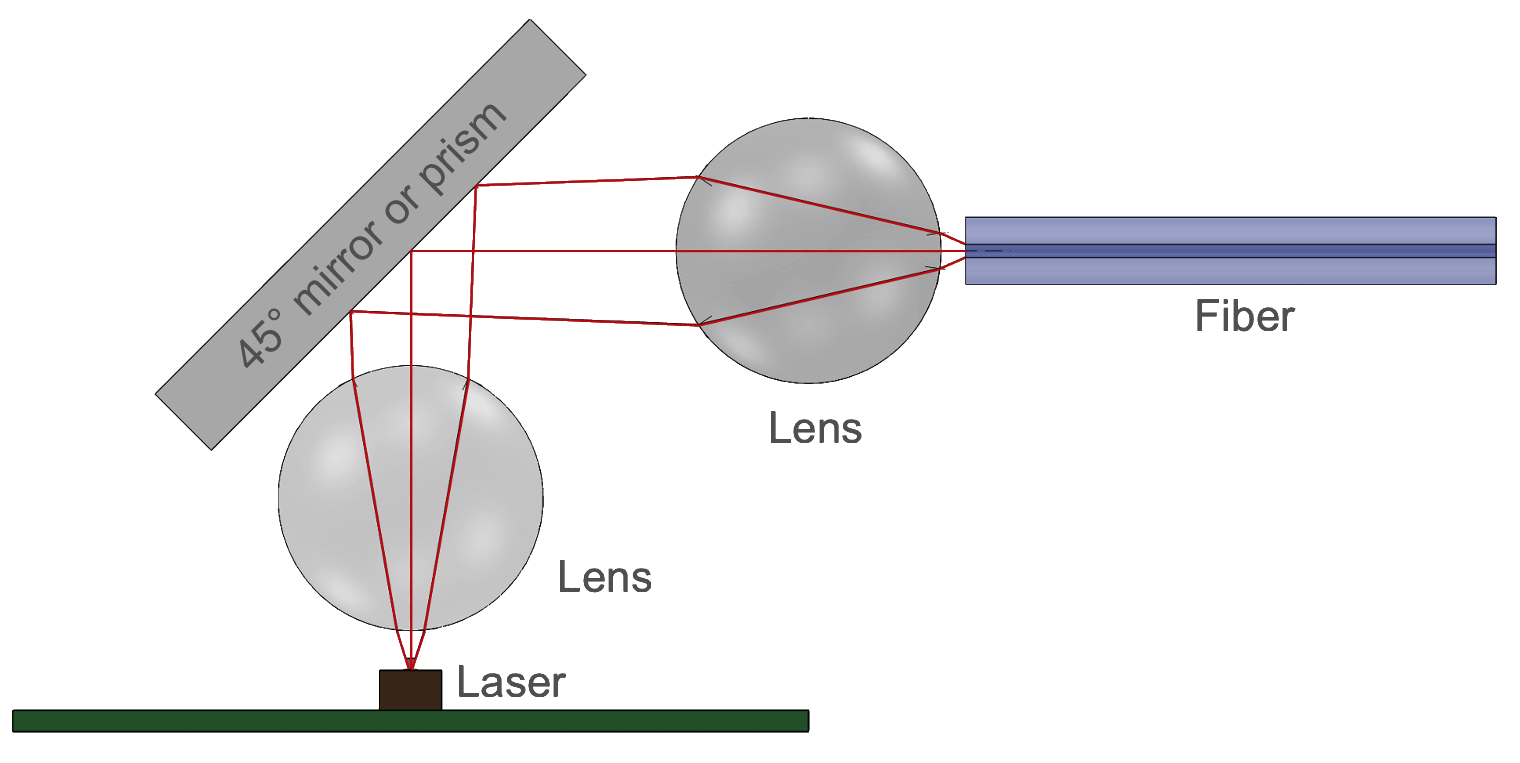

Lens-prism (or mirror)-coupling is the mostly used alignment methodology in the fiber optic industry. Light emitted from a laser will be focused by a lens and with help of a prism or 45° mirror reflected towards the optical fiber. A second lens may further focus the light before it finally is coupled into the fiber. This described optical engine works bi-directionally, allowing to use usually the same optical engine on the photodiode end of an optical system. The figure below depicts the lens-prism coupling principle in a simplified manner.

Simplified Lens-Prism Coupling Principle

Due to the wide variety of lens shapes and materials with different refractive indexes, this coupling

principle is suitable for edge emitting semiconductor lasers with their inherent astigmatism as well as for

VCSELs and photodiodes.

At ideal conditions, the coupling efficiency of the lens-prism-coupling can reach up to 90%.

The biggest advantage of the lens-prism-coupling principle is it support of highest data rates.

At the TX side of an optical system, lenses can be chosen to match the numerical aperture (NA) of the fiber,

to excite only lower order modes in the waveguide, and to precisely focus light at the center of a gradient

index profile of a multi-mode fiber.

At the receiver end, lenses help to focus light even on the small aperture of an e.g. 25 Gbps photodiode,

allowing for a low coupling loss, a high signal-to-noise ratio, and thus for a low bit error rate (BER).

Another inherent advantage of the lens-prism-coupling principle is the bending of the optical signal instead of the electrical signal. Especially at highest frequencies this is a tremendous advantage and allows for precise and short electrical connections to the active optical components.

The biggest drawback of the lens-prism-coupling principle is its high costs compared to the simple

butt-coupling principle.

These costs arise out of basically two facts: for one, lens-prism coupling requires next to the precision

fiber guides at least one prism (or mirror) and one lens. Even though, all these components can be

manufactured within one single micro-injection molding process, it remains a “single” device manufacturing

process compared to the wafer-like manufacturing process of optical engines based on the butt-coupling

principle.

The second cost driver is the sensitivity of the lens-prism-coupling principle to linear and angular offsets

of the optical axis.

This usually leads to high yield losses if a passive alignment methodology is used or requires expensive

active alignment processes.

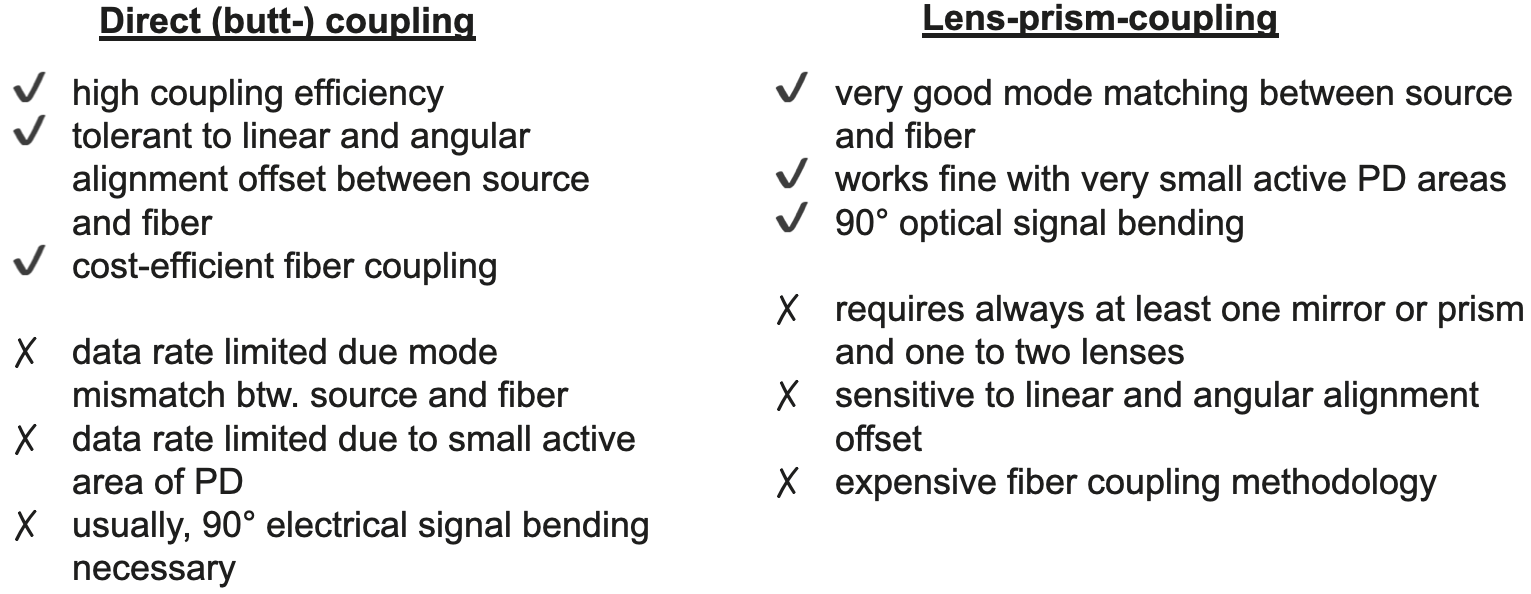

The table below compares the two fiber coupling principles: